In 1889 in the United States, when the pre-surgical disinfectant contained mercuric chloride and carbolic acid (phenol), a nurse named Carolyn, suffered from dermatitis because of long-term use.

It so happened that the medical doctor she was partnered with was courting her and commissioned Goodyear Rubber to build thin latex gloves to protect her lover's hands, and disposable latex gloves were invented, and today, more than 100 years later, latex gloves are used by health care workers all over the world. I have to say that this is a very great invention.

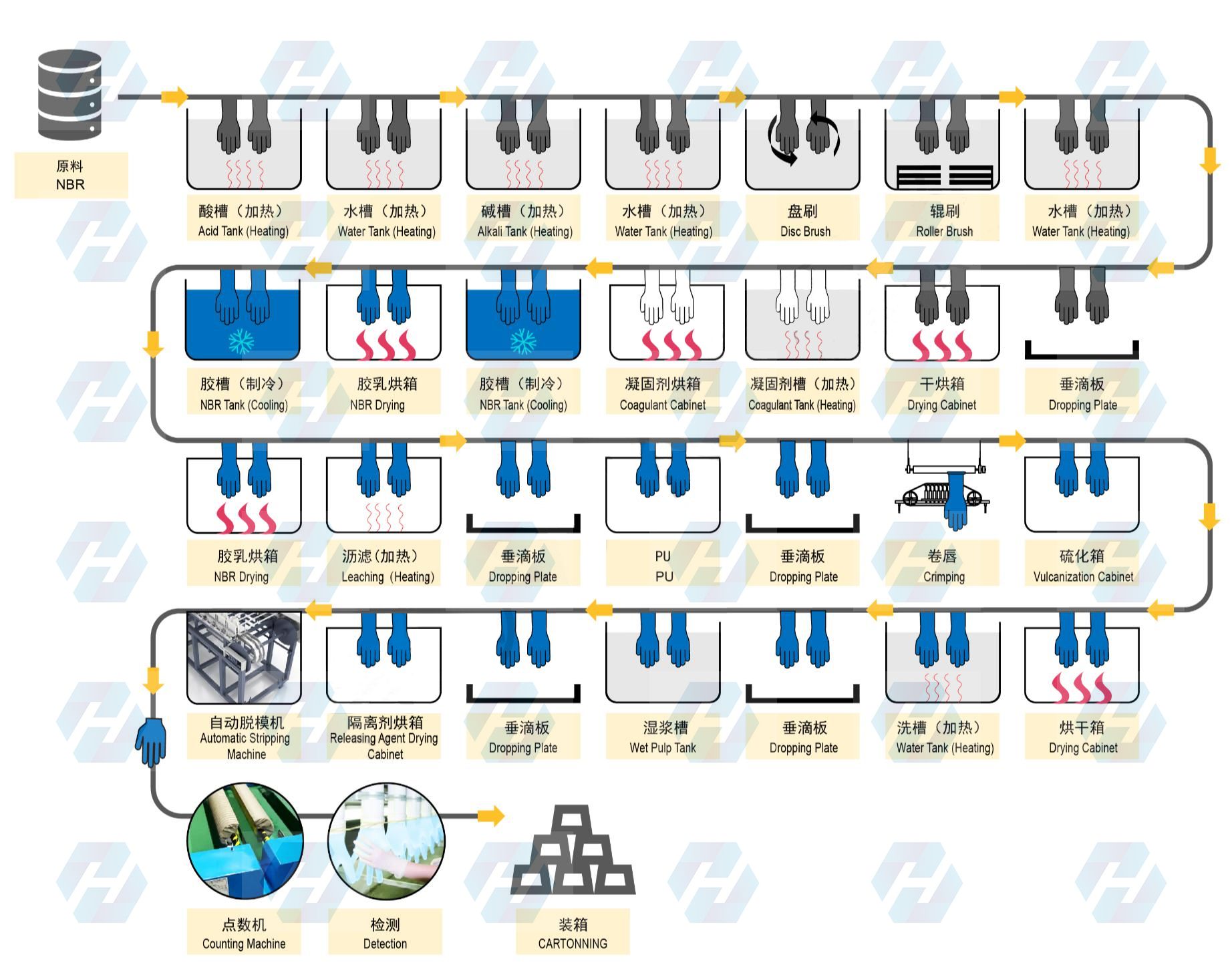

The manufacture of latex gloves requires the use of a very large number of ceramic hand molds, and any tiny particles left on the surface of the molds can cause holes in the gloves and produce defective products, so the molds have to be thoroughly cleaned. It has to be cleaned by soapy water, bleach, brushes and hot water before the prep work is completed.

1. Take turns to go through the acid tank, alkali tank, and water tank cleaning

Used to get rid of the residue of the last time to do rubber gloves, and cleaning while turning, can increase the cleaning strength.

2. Cleaning of disc brush and roller brush

Even the finger crevices can not be spared thorough cleaning.

3. Hot water cleaning

The final part of the residue also washed off together, after several times cleaning, porcelain hand mold has been very clean, does not leave any impurities.

4. Hanging drip dry

Let the hand mold gradually dry, this step is the process of drying while dripping water.

5. Chemical water bath

The liquid latex cannot be directly attached to the ceramic, so a chemical coating needs to be applied to the surface of the hand mold first.

6. Latex coating

When the hand mold is inserted into the warm latex liquid, the chemical coating and the latex will react and become gel-like, completely covering the surface of the hand mold and forming a latex film.

7. Drying latex

Even when drying in the oven, the hand moulds on the assembly line are rotated continuously in order to distribute the latex evenly throughout and to avoid accumulation.

8. Rolling the edges with a brush

Before the latex is completely solidified, use several brushes with an inclined angle to rub the latex gloves a little at a time and gradually roll the edges of each latex glove.

9. Removing the gloves

After the hemming step, the latex gloves are ready.

10. Stretch and inflation test

This is the test that every latex glove must undergo.

11. Sampling and filling test

A sample of latex gloves from a production batch will be tested for water filling, but if any of them fail, the whole batch will be invalidated.

Production line partial photo

Disposable latex gloves are divided into the following three levels.

1. mostly used in the food industry with powder disposable latex gloves, the production process is necessary to join to avoid gloves stick together, in order to facilitate wearing. Special attention should be paid to the fact that there are good and bad corn flour. We use edible grade corn flour, otherwise it is not good for the user, and the object to be served.

2. Powder-free disposable latex gloves are mostly used in electronics and medical industries, because they are just produced with powder, after our processing-water cleaning and come out powder-free latex gloves.

3.Purified disposable latex gloves mostly used in precision electronics and medical industries, which are made of powder-free latex gloves that have been cleaned with water and cleaned again with chlorine, with a cleanliness of one thousand levels.

Post time: Dec-01-2021