We see a lot of masks, clothing is the use of cloth-making machinery to production, and these devices are in the production of the corresponding process, each process is very important, and the corresponding process of different equipment are different, take pp spunbond nonwoven fabric machine process and ordinary mechanical equipment process is different, then the process of spunbond nonwoven machinery is what kind of it?

The basic process of pp spunbond nonwoven fabric machine is: feeding (nonwoven web), folding, acoustic bonding, cutting, bag making (punching), waste recycling, counting, stacking. In order to further realize the role of energy saving and environmental protection, it has the function of residual material recycling in the production process, which collects the leftover waste from bag making in the production process actively, which helps to use it twice, reduces the labor intensity, increases the working efficiency, and also fits the concept of environmental protection, and can save the corresponding cost. Spunbond nonwoven machinery will continue to increase the width of the machine, improve the speed and capacity of the single machine development, pay attention to equipment processing precision and the use of new materials, progress in the level of mechatronics, further use of computer online detection control and network systems to ensure high production and high quality production.

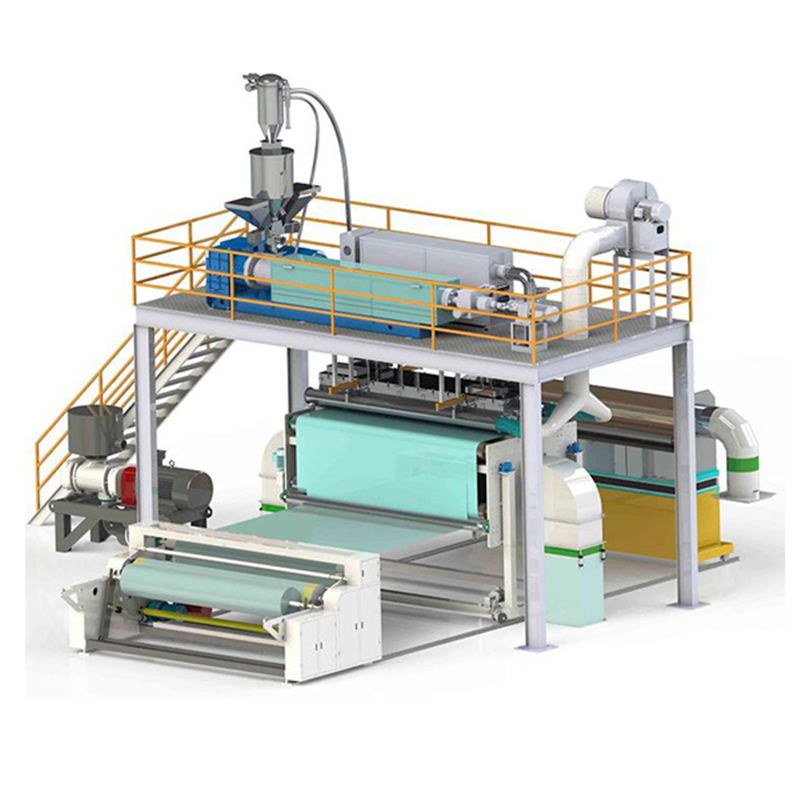

The advantages of choosing spunbond nonwoven production line

Spunbond nonwoven production line after years of practical theoretical summary of the planner, the air duct selection common slit type all drafting planning, to ensure that the fiber network spread evenly, fiber fineness to about 3 denier, the product of the longitudinal and horizontal strength to reach or exceed the national standards. Equipped with advanced touch screen control automatic tracking, over temperature and over pressure alarm system. The mill selects the direct activity force, hard gear reducer, high stability universal coupling transmission, the bearing selects the oil cooling over-temperature lack of oil alarm system, the roll surface selects the perimeter punching technology to ensure the divergence of the overall temperature. The box planning is advanced, and the fluid distribution is evenly distributed to ensure that the waste products are not filamentous, not parallel filamentous, and no holes, so as to improve the product qualification rate. And spunbond nonwoven production line is also relatively simple to operate, the user is easy to get started.

Following the rapid development of society, modern spunbond nonwoven production line manufacturers on the time and efficiency requirements are increasingly high, the spunbond nonwoven production line is presented not only to improve the efficiency and use is also very convenient, so once put into the market is very popular. And occupy a place in the market. The future demand for spunbond nonwoven production line will be bigger and bigger, and the development of this industry will be better and better.

Post time: Jan-18-2022